KING COIL SPRINGS

Kings Springs exclusively use high quality, high stress X5K spring steel.

This new generation steel allows King Springs to further improve many of their existing designs by reducing the amount of steel required in a spring, making it substantially lighter (by approximately 30%) and reducing the solid height therefore increasing travel. Being of particular benefit at all top levels of Motorsport, this new high stress material was introduced to the leading v8 super car teams (inc DJR/TP, FTR & NISSAN) in early 2007 giving a hugely successful endorsement of its characteristics & proven durability.

Although considerably expensive, King Springs have introduced this new high stress steel to their passenger car and 4wd designs which benefit the most at no extra cost to the consumer. As of now all King Springs manufactured coils are now in X5K material.

Height Options

Many of our springs are designed to cross reference and give various height options on some vehicles. This information is too diversified and complicated to be printed and is often conditional. Please consult our technical staff if specialist height options are requested.

VEHICLE RIDE HEIGHTS (centre hub to guard)

An extensive library of vehicle ride heights is being compiled and this information is available to all customers.

Car Coils

Please note: The following height classifications are a generalization only. Degree of lowering can vary between part numbers and vehicles. Spring design i.e. spring rate and vehicle height is relative to market demand. If exacting measurements are required for vehicle ride heights please contact King Springs.

- Front Low: Lowers vehicle approximately 30mm below standard.

- Front STD: Standard Height.

- Front Raised: Raises vehicle approximately 20mm above standard (recommended for bull bar, country driving or whenever increased ground clearance is desired).

- Rear Low: Lowers vehicle approximately 30mm below standard.

- Rear STD +:Standard height to 20mm raised.

- Rear Raised: Raises vehicle approximately 30-40mm above standard (recommended for excessive towing, load-carrying or LPG tank etc)

NOTE: Super Low coils are generally 40-50 below standard.

4WD & Ford "F" Series Coils

- Front and Rear STD: Raises vehicle approximately 10mm-20mm above standard.

- Front and Rear RAISED: Raises vehicle approximately 30mm-40mm above standard.

- Note: All heights mentioned are a generalisation only. Vehicle ride heights can vary, depending on:

- Life and/or age of vehicle

Accessories fitted to the vehicle

Factory options (Country Pack, S Pack etc.)

When discussion vehicle ride heights, consider all of the above and advise customers accordingly.

LPG - For cars fitted with LPG tanks use part No. in Raised column to sit Std. Height.

Measuring Coil Springs

Listed below is relevant information required when identifying or measuring coil springs.

- Free Length: The length of the coil at it's longest point out of the vehicle not under load. To measure, lay coil flat, butt one end to flat surface at right-angles with coil.

- Open Strut Length/Trapped Length: The length of the coil when vehicle body is jacked up and all load is removed from spring (except pre-load).

- Static Length: The length of the coil in the vehicle as it stands under normal load.

- Inside Diameter: The width of the spring at it's widest point from inside edge to inside edge.

Note: Check both ends, as many coils can reduce at one end only or be conical in design.

- Total Coils: The total number of complete turns from start to finish (including reductions if any).

- Material Diameter: (Check with verniers) Note: Check end coils as diameter may decrease.

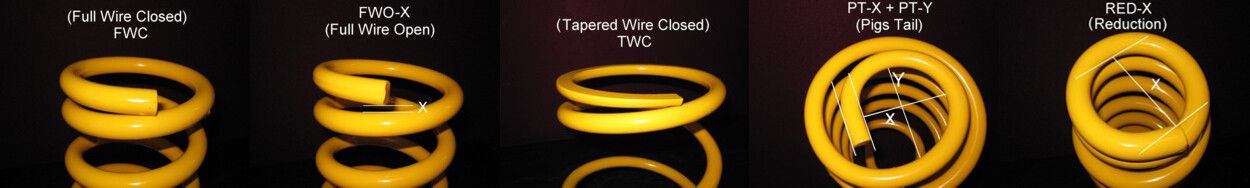

- End Configuration: There are several types of end finishes:

i. Normal: (not ground, straight cut) Note: Measure end gap at tip to next coil (FWO-)or (FWC-)

ii. Ground: Ground flat (TWC-)

iii. Pigs Tail: End reduces greatly and will fit inside the coil below (PT-)

iv. Reduced: End coil will sit on top of coil below. (RED-)

Trouble Shooting (Coil and Leaf Springs)

- Kings Performance Replacement Coil Springs in both STD and Raised Heights are often shorter than the springs they are replacing. This is because they don't compress as far under the initial pre-load or weight on the vehicle.

- When sorting vehicle height problems, be sure that all wheel and tyre sizes and type pressures are compatible. Measure all four corners. Measure centre hub to guard, with vehicle on flat surface.

NOTE: Most vehicles transfer weight diagonally.

- Many Part numbers listed in the catalogue have a driver's side and passenger side and are marked accordingly.

- Wheel alignment is recommended after having front springs fitted on all vehicles. Some vehicles require wheel alignment on rear when rear springs are fitted. Refer wheel alignment specialist.

- Allow 4WD Leaf Springs settling time of approximately 500klms then check and re-tighten all U-bolts and Shackles

KINGS PERFORMANCE TAPERED WIRE / PROGRESSIVE RATE COIL SPRING

"The Intelligent Coil Spring"

There is no disputing the advantage of increasing the spring rate in a vehicle to improve vehicle stability and load carrying capacity, however, in many vehicles we are often confronted with three major considerations:

- Ride Comfort

- Shock Absorber Control

- Spring Entrapment

RIDE COMFORT is always a consideration. The spring rate must increase enough to give improvement without causing undue harshness.

SHOCK ABSORBER CONTROL - The shock absorber obviously plays a vital role in controlling a vehicle's stability. Excessive spring rate can often find shock absorbers struggling to control the vehicle (lack of rebound control).

SPRING ENTRAPMENT - When an increase in spring rate and decrease in vehicle ride height is required, spring entrapment can become a problem. Previously, the only solution being a compromise of minimal increase in spring rate and/or minimal decrease in vehicle ride height giving unsatisfactory results (suspension bottoming or not low enough).

ENTER KINGS PERFORMANCE TAPERED WIRE / PROGRESSIVE RATE COIL SPRINGS

Progressive rate springs are the ultimate in spring design. The principle is simple. The spring rate increases when you need it (cornering, load carrying etc.) and decreases it when you don't. The science behind designing a progressive rate coil is knowing over what suspension travel and to what degree the spring rate will increase. This varies greatly between vehicles. Referring to the above 3 conditions with Kings Tapered Wire / Performance Progressive Rate Springs a substantial spring rate increase is achieved with minimal loss of ride comfort as the spring rate increases and decreases where necessary. As the spring de-rates (the spring rate decreases) the shock absorber no longer struggles for rebound control and gives improved vehicle stability.

With Kings Performance Tapered Wire / Progressive Rate Coil Springs, spring entrapment problems are now often solved with substantial spring rate increases and ride height decreases available.

KINGS PERFORMANCE TAPERED WIRE / PROGRESSIVE RATE COIL SPRING

"The Intelligent Coil Spring"

Progressive Rate Design Principles

Remembering the principle, 'the less coils in a spring, the higher the spring rate' as the spring compresses under load the gathered coils come into contact and become inactive thus increasing the spring rate. The point at which each coil comes into contact and the rate of increase is the result of extensive research, development and testing on advanced testing equipment.

De-Rate

Kings Performance Tapered Wire / Progressive Rate Springs in most cases are designed around the De-rate principle, i.e.; the critical part of the suspension travel from ride height back to full suspension drop. The aim is to allow the spring rate to decrease smoothly back to original spring rate or as close as possible.

Example:

Original Spring Rate 120lb/"

Heavy Duty Linear Spring Rate 160lb/"

King Performance Progressive Spring Rate 130lb/" to 200lb/"

Result:

The above progressive rate spring would have similar or more improved ride quality than the heavy duty spring with a substantially higher spring rate being achieved at ride height.

Please Note: Tapered Wire / Progressive Rate Springs are not necessary for all vehicles and are only used in specific vehicles recommended by King Springs depending on suspension type and spring travel.

King's Tapered Wire / Progressive Rate Springs have the unique ability to allow many part numbers to cross reference not only between different vehicles but also front and rear. As the load varies in all cases, the spring rate adjusts accordingly