FRONT RECOVERY POINTS

MEDICAR FRONT RECOVERY POINTS PX/PXII/PXIII FORD RANGER - FORD EVEREST - MAZDA BT50 2012 ON

PAIR $299

RATED 10 TONNE

FITTING INSTRUCTIONS VIDEO LINK : https://www.facebook.com/MedicarAutomotiveSolutions/videos/2168437493448250

CLICK FOR CATALOGUE - NEW COMING SOON

Recovery is an inevitability when four wheel driving. You need rated recovery points that can safely withstand and distribute the loads of a recovery – which is something stock tow points aren’t designed to do. Ironman 4x4 is releasing our new rated recovery points range.

Ironman 4x4 has created recovery points that are both rated and designed to be fitted (and sold) in pairs, allowing an equalisation strap to be used and provide multiple attachment points during a recovery.

Powder coated red for ease of identification – especially when covered in dirt and mud, Ironman 4x4 recover points are perfect for winching and snatch recoveries.

With holes to suit a 4.75t shackle, hooking up is simple and compatible with your standard recovery kit.

NON VEHICLE SPECIFIC

UNIVERSAL RECOVERY HOOK

Ironman universal tow hooks provide an additional recovery point for your 4WD.

These Tow Points have been designed and tested for straight line pull. The Tow Points have not been tested for lifting purposes & should not be used for lifting, the forces applied differ between lifting and straight line pull type recoveries. Roadsafe Tow Points are FEA Tested during design and Destruction tested during development to establish Working Load Limits.

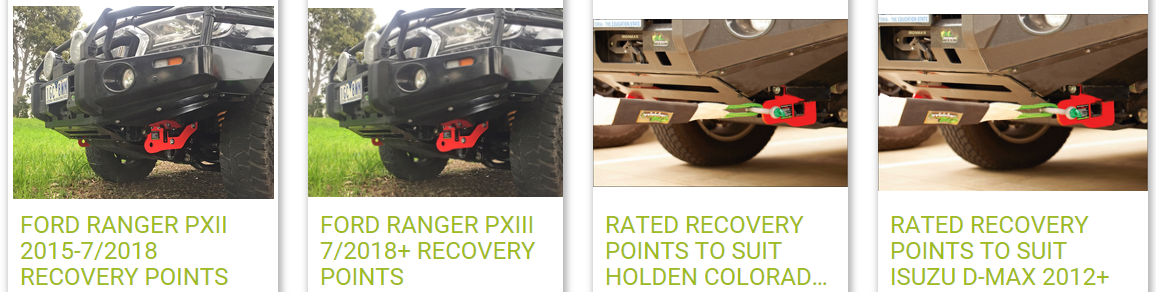

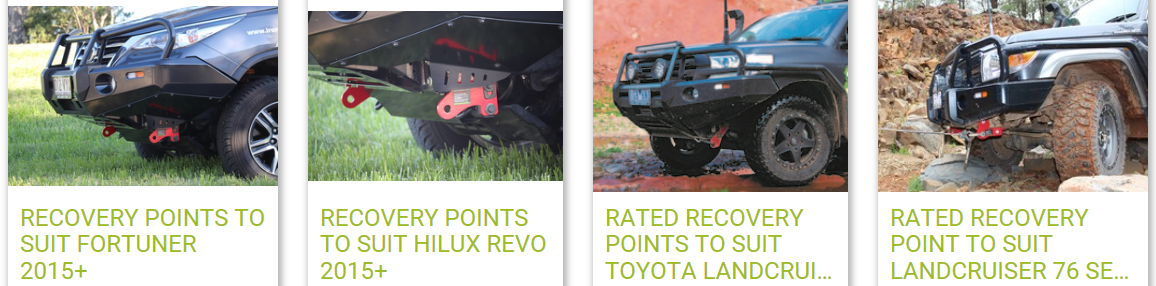

Tow Points are currently available for the following vehicles…

Ford Ranger PJ-PK – RP-RAN01

Ford Ranger PX – RP-RAN02 (Australian Design Registered – AUST DES REG. 366315 (201516778))

Holden Colorado RC – RPCOL01 (Australian Design Registered – AUST DES REG. 201810097)

Holden Colorado RG – RPCOL02 (Australian Design Registered – AUST DES REG. 366332 (201516772))

Isuzu D-Max 2012-on – RPCOL02 (Australian Design Registered – AUST DES REG. 366332 (201516772))

Isuzu MUX 2012-on – RPCOL02 (Australian Design Registered – AUST DES REG. 366332 (201516772))

Mazda BT50 Gen 1 07-11 – RPRAN01

Mazda BT50 Gen 2 2011-on – RPRAN02 (Australian Design Registered -AUST DES REG. 366315 (201516778))

Mitsubishi Triton ML-MN – RPTRI02

Mitsubishi Triton MQ – RPTRI03 (Australian Design Registered – AUST DES REG. 201714737)

Nissan Navara D22 – RPNAV22

Nissan Navara D40 – RPNAV40 or RPPAT04

Nissan Navara D23 (NP300) – RPNAV23

Nissan Patrol GQ-GU I – RPPAT01

Nissan Patrol GUII-V – RPPAT04

Nissan Patrol Y62 – RPPAT62 (Australian Design Registered – AUST DES REG. 201810098)

Toyota FJ Cruiser – RPPRA150

Toyota Hilux (KUN) 2005-15 – RPHIL05V2

Toyota Hilux (GUN) 2015-on – RPHIL15 (Australian Design Registered – AUST DESIGN REG 201711968)

Toyota Landcruiser 70 series (not 75) – RPCRU70

Toyota Landcruiser 70 series (not 75) – RPCRU70E (extended length to clear bash plate)

Toyota Landcruiser 75 series – RPCRU75

Toyota Landruiser 80 Series – RPPAT04

Toyota Landcruiser 100 Series – RPPAT04

Toyota Landcruiser 105 Series – RPPAT04

Toyota Landcruiser 200 Series (to 12/14) – RPCRU200

Toyota Landcruiser 200 Series (to 12/14) – RPCRU200V2 (Australian Design Registered – AUST DESIGN REG 201810224)

Toyota Prado 120 – RPPRA120

Toyota Prado 150 – RPPRA150

Volkswagen Amarok – RPAMA01 (Australian Design Registered – AUST DES REG. 201610654)

If a recovery is to be performed, it is imperative both Tow Points are utilized, with the use of a bridle strap. This will share the load through the front of your vehicle, giving increased strength and safety margins, the use of a bridle strap will also keep all components tethered in the case of a failure, reducing the risk of serious injury or death.

Always INSPECT the Tow Points and shackles before each use. Do not use if there are visible signs of damage or wear (including cracking or elongation). Do not exceed the Working Load Limit (WLL) of the shackle or Tow Points. Always STAY A SAFE DISTANCE away from the recovery area – at least 1.5 times the length of the recovery strap. Incorrect use of recovery equipment can result in serious injury or death.

Always ensure that adequate PREPARATION for the recovery, to minimise the strain on either vehicle, has been undertaken i.e. Digging, Rock placement etc. If you do not understand how to use this equipment safely or are uncomfortable with your abilities in the use of recovery equipment, please complete a course that specialises in four wheel driving & 4WD vehicle recovery.

Check out a great article on Recovery Points here…

RECOVERY POINTS

Strong, reliable recovery points are essential for off road driving but the lack of industry standards regarding rated tow points has caused confusion among four wheel drivers for many years. With this in mind, ARB has sought to set an industry benchmark for how recovery points are designed, tested and selected by 4WDers.

ARB’s recovery point range seeks to address issues surrounding generic tow points and their unsuitability for a range of recovery situations. These issues include questionable and untested mounting locations, confusion regarding the selection of rated shackles and straps, and the inability of generic tow points to safely handle stresses generated by an angled pull during vehicle recovery.

ARB aims to make it easy to find the correct recovery point for each individual customer with an engineered ‘Recovery Train’ in which each vehicle specific recovery point is rated for use with a 4.75t rated bow shackle and 8000kg snatch strap.

RESEARCH AND DESIGN

Each ARB recovery point undergoes considerable research and design involving actual vehicle chassis samples and CAD data relating to critical front sections of the vehicle. Dozens of designs are explored, with the more promising models built into prototypes and tested on the actual vehicle chassis using ARB’s various load and destructive testing equipment.

VEHICLE SPECIFIC MOUNTING

Some vehicle models demand very complex mounting systems to ensure fitment does not affect air bag deployment in the event of an accident. With months of design and testing dedicated to each individual recovery point, ARB’s engineers ensure that the crash pulse of the vehicle remains unaffected, whilst also ensuring the recovery points are fitted in the optimal location to handle the stresses experienced during vehicle recovery.

RATED FOR ANGLED RECOVERY

ARB recovery points are rated in an angled direction of pull and this has been achieved for angles up to the maximum turn angle of the front wheels of the vehicle. The design features a long slot as it allows the bow of the shackle to be fed through and the strap attached via the pin instead of the bow. This allows the shackle to pivot within the recovery points to avoid side loads on the pin.